Since 1937

The Salice family

Paolo Salice creates his line of classic handles at the turn of the 40-50s, taking advantage of the know-how acquired in brass working in his mechanical workshop. Cantù and its territory make precious artisanal resources available to him, including designers, carvers and expert chisellers, in order to evolve the range together with his son Bruno.

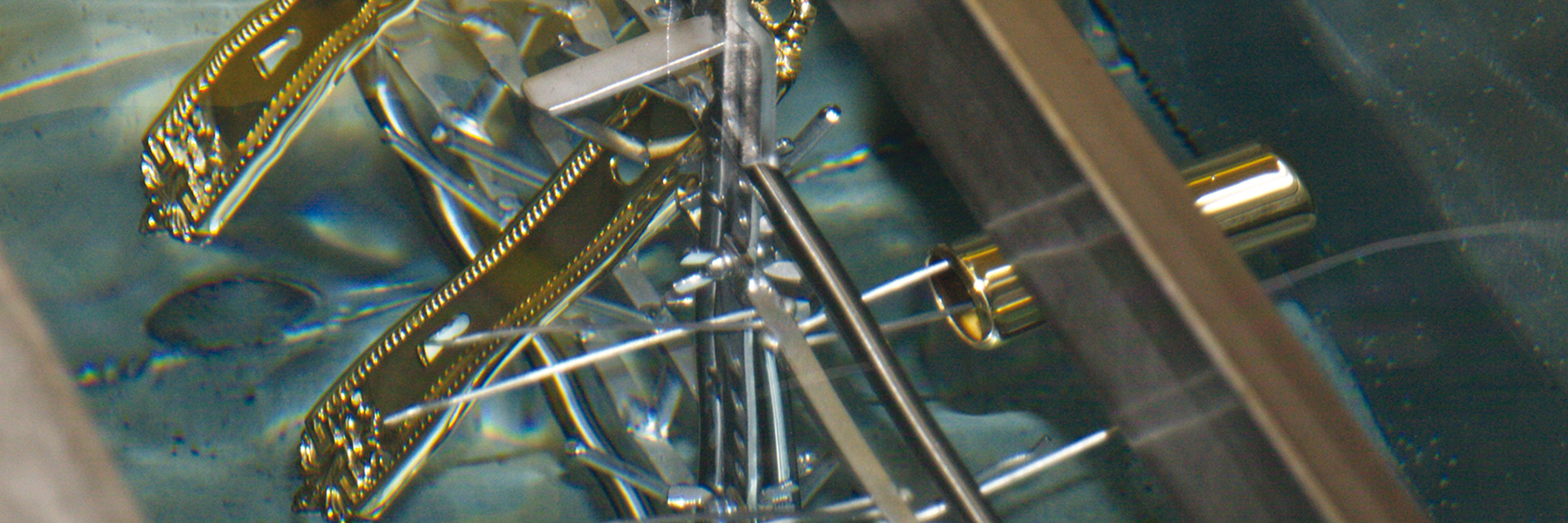

Technique, culture and artisan skills come together today in a complete range of styles and finishes, positioned at the high end of the market. In the historic Cantù plant, highly automated systems and manual processing alternate with process water and air purification technologies that comply with the latest regulations. The installation of water degreasing tanks totally eliminates the use of solvents, even those currently declared non-harmful.

Now in its third generation, the Salice family guides the brand towards a constant evolution, respecting its uncommon tradition and in defense of a genuinely Made in Italy production

Range extension

Salice Paolo offers a complete range of elements and accessories able to furnish an environment in a complete way and to respond to all the practical and aesthetic needs of its customers. On the Salice Paolo website, each product sheet presents a visual and immediate system to check all the possibilities for your project, showing accessories from the same family or compatible.

The complete catalog consists of:

- Handles

- Cremonesi and Dreykipp

- Pull handles

- Knobs

- Flush handles

- Entrance set

- Entrance set Yale

- Accessories Furniture handles and decorations

- Bathroom accessories

Design

Talking about the workflow that involves craftsmanship including hand drawing, chiseling, followed by all the most modern design systems.

All Salice Paolo models are designed in house (in the image above, Bruno Salice at his drafting machine, 2012). The company also makes use of highly experienced collaborators in the classic furniture sector and designers such as Itamar Harari who offer their alternative vision in a traditional but constantly evolving field. A key concept of the Salice Paolo philosophy.

The quality

The uncompromising quality of true Made in Italy: from the idea to the design, from the molds to the finish and checks on each individual piece.

Control of each piece at all stages of finishing: this means an unrivaled quality standard with automated management or random checks.

The whole range is made of brass, the best material to guarantee finishes free of defects, high resistance to chemical and atmospheric agents and, last but not least, for the maximum sensation of weight and solidity to the grip.

Finishes

The finishing processes highlight the final quality of each Salice Paolo product.

Galvanic baths with precious materials, complex hand-made processes, unique finishes on the market: the constant goal is an authentic and lasting effect, typical of high craftsmanship.

Glass and crystal

Brass is contrasted by the visual lightness of transparent materials, chosen on the basis of the design of the individual model and the required optical properties. All products with glass and crystal parts are tested to withstand the expected bending loads.